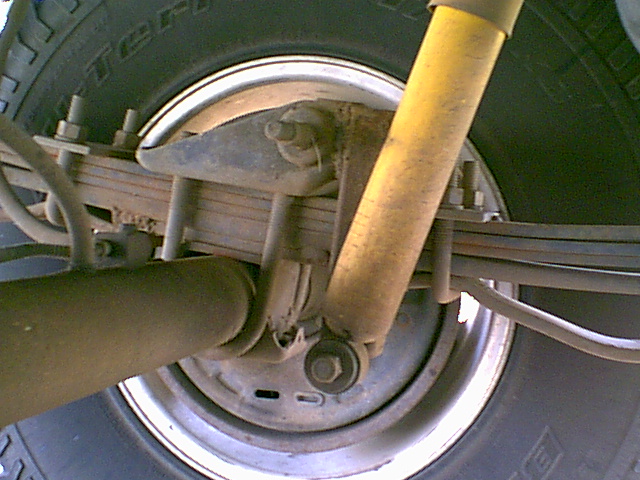

Thats pretty much it for the rear.

Lets go to the front

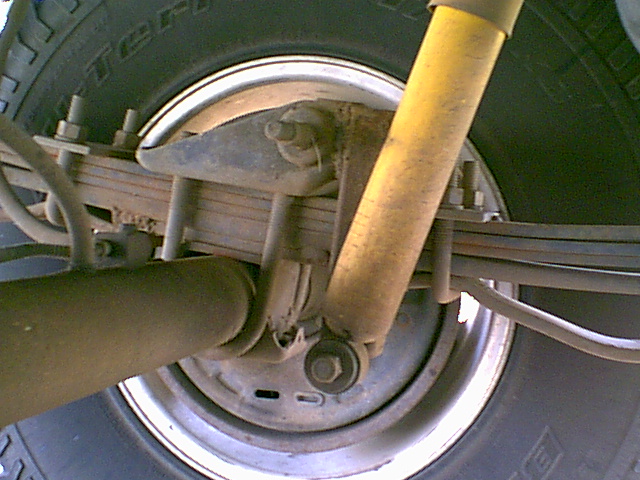

Rear Drop Pitman cut Control

Arms Track Bar Drop

If you want to know how to get your JEEP in the air, this is how I did it. I don,t get in

to any other lift for the simple fact that I have never done any other. It took me about

six months to figure everything out and to get the truck to ride right. To some that may

seem like a long time, but you must remember, this is my first 4 wheel drive and the only

one I've ever done.

One other thing you must remember is that with the exception of the lower control arm

bushings and the front coil springs, I have done all the fabrication. I've done all the

welding cutting and fitting. I've made a lot of mistakes and it took me awhile, but I now

have an excellent riding truck that is a daily driver and am very happy with it. If you

want to buy a pre made kit I would have to say Tomkin's would be the best. This is because

they gave me advice when no one else would. They didn't care if I had there kit or not. I

eventually bought their front springs and bushings and I'm very happy with the quality of

the product.

But anyway, on to the lift

First of all you will need some jack stands (tall ones) and a good jack to get the truck

high enough to do the lift. I highly recommend to do this in a garage if at all possible.

If you have all the parts ready and are an accomplished mechanic you can do this in one

day ( but don't plan on it). If not it could take a while. Special tools you will like to

have is an air supply for air tools (defanent plus), Mig welder and a grinder. If you

don't know how to weld, find somebody that can and is good (preferably certified). I don't

recommend any welding be left to the novice. This is the main part of the truck your

messing with so if you bugger it up and it falls apart while you are going down the road

you will get hurt, BAD!

Lets do the easy part first. Get the truck up as high as the jack stands will safely let

you go. Now get the wheels off and stack them to the side.

Lets start at the back of the truck. First make sure the jack stands are under the frame

and not the axle. If they are under the axle when you on bolt it, things are going to get

ugly because it starts out as a spring under set up (I've seen people pull this trick

before so don't laugh).

Now that everything is hanging by its self, put the jack under the chunk for now and snug

it up. Remove as follows. Drive shaft,drums, shocks (you will have to jack the axle up a

little to do this) brakes and emergency brake cable, brake line at the T, and the axle U

bolts (after you relieve the jack pressure on the axle so its hanging free). After

that raise the axle up a little so its just of the springs and support it with jack

stands. Now undo the shackles one at a time and lower the rear of the springs to the

ground. Once this is done you should be able to slide the axle out the back of the truck

on the jack. When you get this done go ahead and remove and install the new or put the old

springs back in the shackles and tighten them back up.

One thing about the springs, I don't recommend using the stock spring as they are,

because, you will run into torque steer and axle wrap up problems. If funds are a problem

at least go to the nearest auto parts store and get a set of bolt on helper springs. This

will work until you can get a new main leaf or complete leaf pack of a higher spring rate.

Now that the axle is out and you can get to it, you need to weld on the new spring

perches. Use a measuring tape to measure from the original perch to the new so your pinion

angle is the same (pic to come soon). If it's not you will get a roar and vibration out of

the rear of the truck.

Get this done and put it all back together like you tore it apart except the axle is on

the bottom of the spring. Depending on your truck you might have to get the drive shaft

lengthened so it wont come out of the back of the transfer case. I didn't. even under full

drop my shaft stays in just fine. This is something that you will have to figure out your

self. You need at least 1 inch of compression space so the shaft won't bottom out on the

transfer case.

The only other problem you should have is the shock mounts and the brake line. You will

need to ether relocate the upper brake hose block lower, or get a longer flex hose. As for

the shocks, you need relocate the lower mounts. I used a piece of 1 inch box tubing and a

5/8 bolt for a mount. I hope to have pictures soon for all of this so please stay tuned.

Thats pretty much it for the rear.

Lets go to the front